Valve & Seat Concentricity

Blog

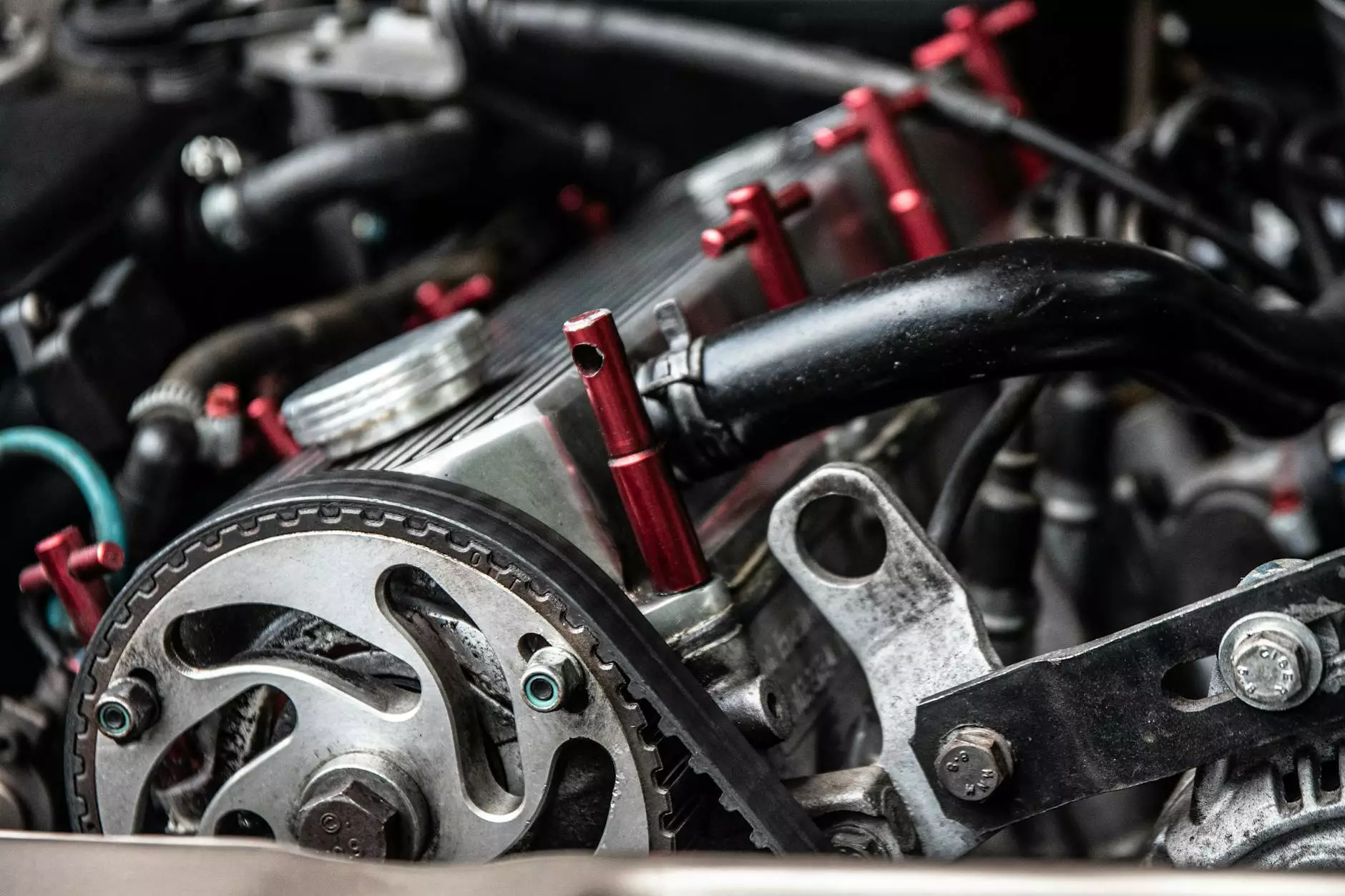

Welcome to Rusty's Upholstery, your ultimate destination for all things related to valve seat concentricity. In this Tech Lab Tuesday video, we delve into the world of automotive engineering and explore the significance of valve and seat concentricity for optimal engine performance.

What is Valve Seat Concentricity?

Valve seat concentricity refers to the alignment of the valve and the valve seat within an engine cylinder head. This alignment plays a crucial role in ensuring efficient combustion and power delivery, making it a vital aspect of engine performance. When the valve and seat are properly aligned, it allows for effective sealing, minimizing exhaust emissions and maximizing power output.

The Importance of Valve & Seat Alignment

Proper valve seat concentricity is crucial for several reasons. First and foremost, it ensures effective compression sealing, which is essential for maintaining engine performance. When the valve and seat are aligned correctly, there is minimal leakage, allowing for higher compression ratios and improved power delivery.

Additionally, accurate valve seat concentricity contributes to better heat dissipation. By aligning the valve and seat, heat transfer is optimized, preventing overheating and potential damage to the engine. This is particularly important in high-performance engines where heat management is crucial for optimum operation.

Furthermore, valve seat concentricity plays a significant role in reducing valve and seat wear. When the alignment is off, there is increased friction and wear between the valve and seat, leading to decreased efficiency and potential engine damage. Proper alignment minimizes wear, ensuring longevity and reliability.

The Process of Achieving Valve & Seat Concentricity

Obtaining proper valve and seat alignment requires meticulous attention to detail during the engine assembly process. Here are the key steps involved:

- Valve Seat Cutting: The first step is to cut the valve seat using precision tools and techniques. This involves machining the seat to the specific angles and dimensions required for optimal performance.

- Valve Lapping: After the valve seat is cut, the valve is lapped against this seat. Lapping creates a perfect seal and ensures proper contact between the valve and seat surface. It is a critical step in achieving concentricity.

- Valve Guide Inspection and Replacement: It is crucial to inspect the valve guide for any wear or damage. If necessary, the valve guide should be replaced to ensure proper alignment.

- Valve Stem Straightness Check: The straightness of the valve stem is checked to ensure smooth operation and optimal alignment with the valve seat.

- Valve Seat Concentricity Measurement: Precise measurements are taken to assess the alignment of the valve and seat. This allows for adjustments if needed to achieve optimal concentricity.

By following these steps and maintaining meticulous attention to detail, engine builders can achieve the desired valve seat concentricity, ultimately leading to improved engine performance.

Conclusion

Valve and seat concentricity are critical factors in engine performance and efficiency. With proper alignment, engines can achieve optimal compression sealing, efficient combustion, and reduced wear. At Rusty's Upholstery, we understand the importance of valve seat concentricity in home and garden - furniture applications and provide comprehensive information to help enthusiasts like you make informed decisions.

Whether you're a professional engine builder or an avid DIY enthusiast, our Tech Lab Tuesday videos provide valuable insights into various automotive topics. Stay tuned for more informative content from Rusty's Upholstery, your go-to resource for all things related to home and garden - furniture!